MRK 6.1 Painting, Coating and Finishing Robot

Fast, Easy, and Customizable Application of Coatings on Complex or Simple Objects Made of Wood, Plastic, Metal, Ceramic or Composites

Previous slide

Next slide

OPERATOR REPEAT PROGRAMMING (ORP)

Operator Repeat Programming (ORP) allows our robots to repeat intricate human movements without complicated programming.

OPERATOR TRAINING ROBOT

ROBOT AUTO REPEATING PROGRAM

VIEW OPERATOR REPEAT PROGRAMMING (ORP) IN ACTION

Features:

The MRK 6.1 painting robot can be configured to meet your specific application. Configurations can include but are not limited to carousel arms, turn tables, lifting platforms, and all controls.

Different Arm Lengths

The MRK 6.1 robot can be produced with different arm lengths to meet your requirement.

Mobility Made Easy

The robot arms are built with very light but strong materials and are pneumatically balanced to achieve high levels of mobilty during the programming stage.

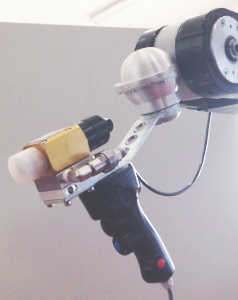

Joystick:

Joystick:

ORP controlled painting and finishing robot is simple and practical, thanks to the use of an ergonomically designed joystick complete with programmable buttons, which allows the operator to manage the programming from the spraying point.

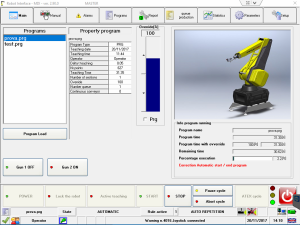

Customized Software:

Our multilingual software can be customized to perfectly meet the needs of customers. It also includes a module for production management with statistics and usage data of the robot. All the robots are supplied with a touch-screen industrial PC, to obtain practical and intuitive management of all the machine’s functions.

Robot Various Configurations:

Robot Accessories:

Various robot accessories are available, including:

- Color Changing Systems

- Rotating Devices

- Lifting Devices

- Nozzle Cleaning System

- Proportional Valves

- RFID Entry

- Barcode Entry

- Conveyor Position Recognition

- 7 Axes Motion Control for Robot Base